PillarWave

An echogram, to visualize in detail the condition of an organ such as the heart or to monitor the absence of a leak in a pipeline for example, is a procedure usually performed by an expert sonographer with expensive and rigid instruments in a hospital or on-site at the industrial plant. TNO has developed and patented a technology in which a flexible patch using ultrasonic takes images of the object (organ, valve…) to be examined over an extended period of time.

Large area image

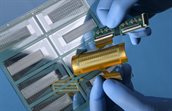

The technology, called PillarWave™, has now been patented and we are in preparation of a spin-off company to commercialize it. Specific structures that emit and receive sound waves are printed on very thin plastic film. Because it is possible to print a great number of these structures over a large area, we can obtain a large image of the object (organ, dataserver, pipeline..) to be examined.

Flexible and affordable

Current ultrasound equipment is rigid and difficult to incorporate in patches. Sensors are small and difficult to scale to large areas, making them quite expensive to make. PillarWave™ technology enables us to make patches or other ultrasound sensors that are ultra-thin and flexible, have a large sensor surface and therefore a large field of view, and are much cheaper to manufacture in large quantities. Instead of silicon, which is expensive when used for large areas, our technology uses plastic as base material.

Reproducible, repeatable images over a longer period of time

PillarWave™ makes numerous applications easier to monitor from a distance. Medical applications are obvious: instead of obligatory hospital visits, patients could be monitored from home or e.g. from their elderly care center. For countries with vast distances, remote monitoring could be a serious upgrade for their health system and patients’ wellbeing.

A wide array of opportunities exist in the industrial and datacenter-world as well. Process plants often cover kilometers of pipes, each welded every so often. Each weld could be a critical point of failure. Existing technologies are not necessarily able to detect potential flaws in their functioning due to the substances that run through the pipes or the geometry and location of the pipes. Moreover, professional people need expensive and often bulky instruments to perform occasional verifications. Imagine you could constantly monitor these pipes and be prepared for sudden events, or be able to prevent an unnecessary intervention via AI-enhanced data-monitoring.

Interested?

Could PillarWaveTM technology benefit your market position? Contact us for investment and/or development opportunities.